MENU

Metal and Rubber Adhesive

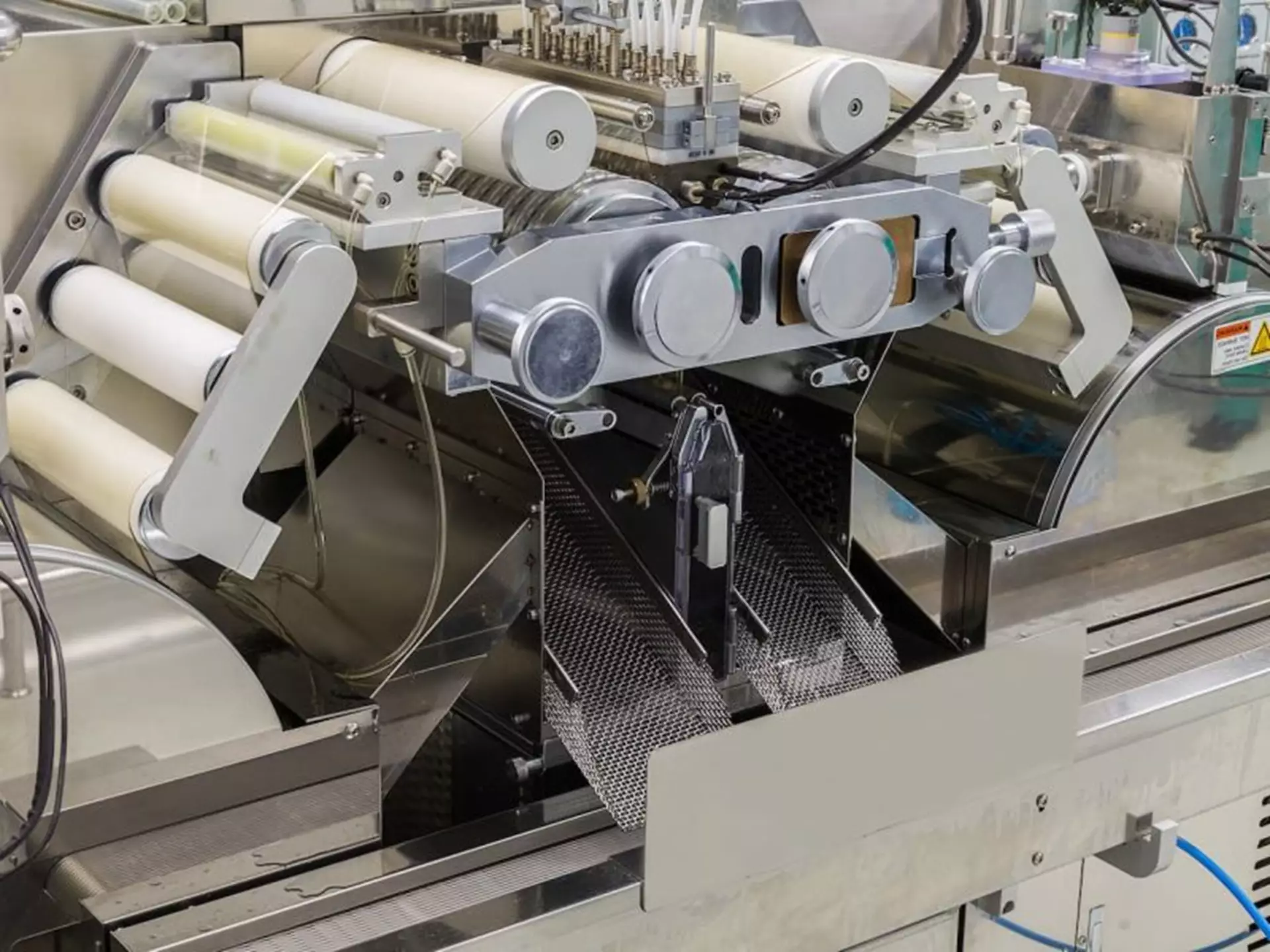

In the realm of industrial manufacturing and repair, the need to securely bond metal and rubber materials is a common challenge encountered across various sectors. Metal and rubber adhesives step in as indispensable solutions, enabling strong and durable connections that enhance productivity and streamline processes. This article delves into the significance of metal and rubber adhesives, outlining their benefits, applications, and factors to consider when selecting the right adhesive for your needs.

Understanding Metal and Rubber Adhesive:

Metal and rubber adhesives are specially formulated bonding agents designed to create resilient bonds between metal and rubber surfaces. These adhesives often incorporate versatile compounds such as epoxies, polyurethanes, or rubber-based formulations. Widely utilized in industries ranging from automotive and electronics to construction and beyond, metal and rubber adhesives offer versatile solutions for various bonding needs.

Benefits of Metal and Rubber Adhesive:

- Strong and Durable Bonds: Metal and rubber adhesives form robust bonds that withstand mechanical stress, temperature variations, and environmental factors, ensuring long-lasting performance.

- Flexibility: With their flexible nature, these adhesives allow for movements and vibrations, preventing cracks or bond failure over time.

- Versatility in Applications: Metal and rubber adhesives find applications in diverse industries, including automotive assembly, electronic device manufacturing, construction, and more, showcasing their versatility and adaptability.

- Ease of Application: Many metal and rubber adhesives come in user-friendly formulations, facilitating easy application and enhancing production efficiency.

Applications of Metal and Rubber Adhesive:

- Automotive Sector: In vehicle manufacturing and repair, metal and rubber adhesives are utilized for bonding rubber seals, gaskets, hoses, and weather stripping to metal components, ensuring optimal performance and durability.

- Electronics Industry: Metal and rubber adhesives play a crucial role in electronic device assembly, bonding rubber components like gaskets and insulators to metal enclosures, providing electrical insulation and environmental protection.

- Construction and Infrastructure: In construction applications, metal and rubber adhesives are used to bond rubberized materials to metal structures, offering waterproofing and vibration dampening properties.

Selecting the Right Adhesive:

- Compatibility: Ensure the adhesive is compatible with both the metal and rubber substrates being bonded, considering factors such as material composition and surface preparation requirements.

- Performance Requirements: Consider the specific performance requirements of your application, such as temperature resistance, chemical resistance, and bonding strength, when selecting an adhesive formulation.

- Application Method: Choose an adhesive application method suitable for your production process, whether it’s manual application, automated dispensing, or pre-formed adhesive components.

- Quality and Reliability: Opt for adhesives from reputable manufacturers known for their quality, consistency, and adherence to industry standards.

Metal and rubber adhesives serve as integral components in various industrial processes, providing reliable and versatile solutions for bonding metal and rubber materials. By understanding their benefits, applications, and selection criteria outlined in this article, manufacturers can make informed decisions when choosing adhesive solutions tailored to their specific bonding needs. With the right adhesive, mastering bonds between metal and rubber becomes achievable, contributing to enhanced product performance and efficiency across diverse industrial applications.